How not to mesh ?

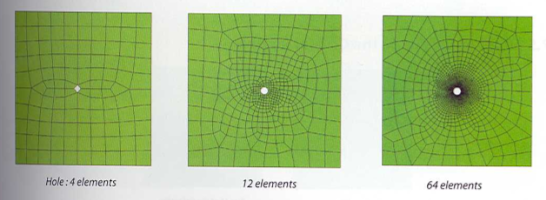

Hey guys, I know this is too late but today we are going to discuss how we did not mesh to our FEA geometry to get successful results. So without wasting time let's get into it. 1) Back-to-back triangle should be avoided. Two tria elements should not be connected to each other directly. You can see this in this image. 2) On the plane surface triangular elements should be avoided. The recommended mesh is shown in the figure. 3) No mesh transition on the constant radius fillets/curvatures. Mesh transition should be carried out on the plane surface. As you can see in the figure this should not be recommended. 4) Avoid tri element on the outer edges and holes. It can cause the wrong results. 5) Some useful and recommended points that are not respectable at the professional level. This is shown in the following figure. 6) Circular hole should be molded carefully with a washer it means fine meshing at the circle. And minimum 2 layers around the hole. 7) Holes should be molded with an ev...