What is Non-linearities in FEA? & What are different types?

Hey guys

Today we are talking about the most important topic i.e. the nonlinearity of FEA.

What is non-lineaities?

We have talked about linear and non-linear analysis. And how they differentiate from each other. Every problem that we encountered in real life is non-linear. But for the sake of simplifying the problem, we do it with the linear analysis.

What is the linear analysis means?

In which for solving any type of problem we considered that the force and the displacement (As an output) are changing linearly. As in the linear analysis the stiffness of matrix doest change it remains constant.

As in the non-linear analysis, there are different types of non-linear analysis. The nonlinearities vary or it depends on various factors there are various types of non-linearites such as a

1) Material nonlinearity

2) Geometric nonlinearity

3) Contact nonlinearity

1) Material nonlinearity

As in Material nonlinearity, we consider the material is nonlinear. Generally, if you consider the material linear it has certain linear behaviors, such as steel. Now if during one of your simulations, you would find a stress value which is higher than the yield point, your linear solver will just continue linearly and therefore create inaccurate high-stress results. In the situation where the stress is beyond the yield stress value, you should define plasticity in the material model and investigate if any failure will be likely. This is what you would do in a Non-Linear Analysis.

You can see in the image as this is a stress-strain curve for the material nonlinearity of steel in which the plasticity of material is enabled

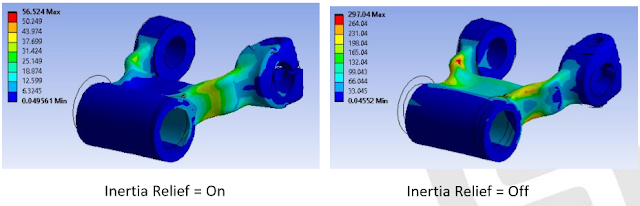

The difference in the material nonlinearity of steel shown in fig as the left is with the linear analysis and on right with the non-linear material

2) Geometric non-linearity

Geometric nonlinearity arises when the changes in the model’s geometry are very high during the course of deformation. such as if the component within the elastic limit but due to very large length even small force causes large deformation. This happens when there are

- Large deformations

- Large rotations

- Both

- Initial loading conditions before the start of the analysis

If you have any difficulty contact us and for more amazing content subscribe to the blog...

THANK YOU !!!

HAPPY LEARNING!!!😃😃😃

Comments

Post a Comment